Representative Name: Nikhil Kumar Joshi / Prashant Patil

Address: #27 First Floor, 18th Cross M.C.Layout, Vijayanagar, Bangalore.

Phone No: +91 80 412 75612 Mobile No:+91 99000 74532 Email: sales@snic.co.in

Timer Pro – Measurement and Continuous Improvement

Timer Pro is the complete video-based measurement solution for those involved in Continuous Improvement, Automation Modeling, Lean Manufacturing, Industrial, Manufacturing and Process Engineering, Ergonomics, Operator Training, Six Sigma, Kaizen, SMED and 5S initiatives.

Timer Pro offers a single integrated solution to measure, balance, identify and eliminate process waste to improve operation efficiency, reduce costs and document processes. Whether used with manual, automated or robotic processes, the highly visual Timer Pro interface increases the productivity of both content creators and their operations.

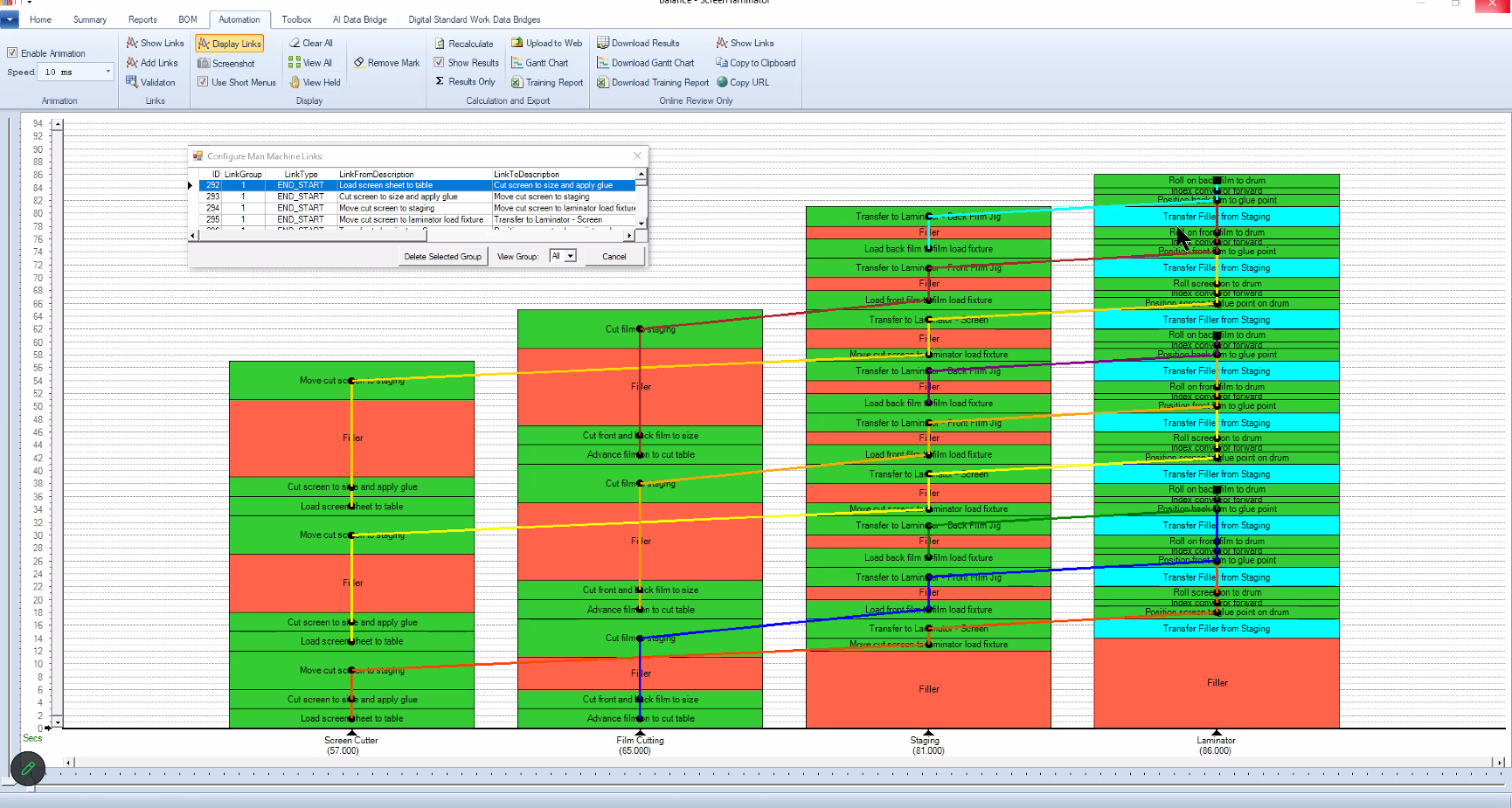

Automation, Robotics and Man-Machine Process Modeling

Timer Pro allows you to quickly create detailed automation, robotic and man-machine process models. The amount of money being invested in these solutions is significant and data to justify expenditures is often subjective and difficult to quantify.

Click Image Below to Enlarge

Models can be created in less than an hour to instantly quantify throughput based upon your process design. You can then explore multiple performance scenarios to support capital expenditures for new processes or optimization opportunities for your existing processes.

Timer Pro’s Video Time Study module is the perfect complement as you create automation models of your current processes.

The actions of your automation assets are consistent. Therefore a single cycle video of your process will give you all the times you need to create an accurate automation model. Video time studies unique features allow you to quickly record each asset’s activity times with millisecond accuracy to support your continuous improvement initiatives.

Examples Where Timer Pro Professional Can Be Used

Over 1600 companies worldwide use Timer Pro in their Industrial, Manufacturing and Process Engineering, Kaizen, Lean and Six Sigma initiatives. Timer Pro’s largest market segment is automotive followed by medical devices, engineered products, consumer products and electronics.

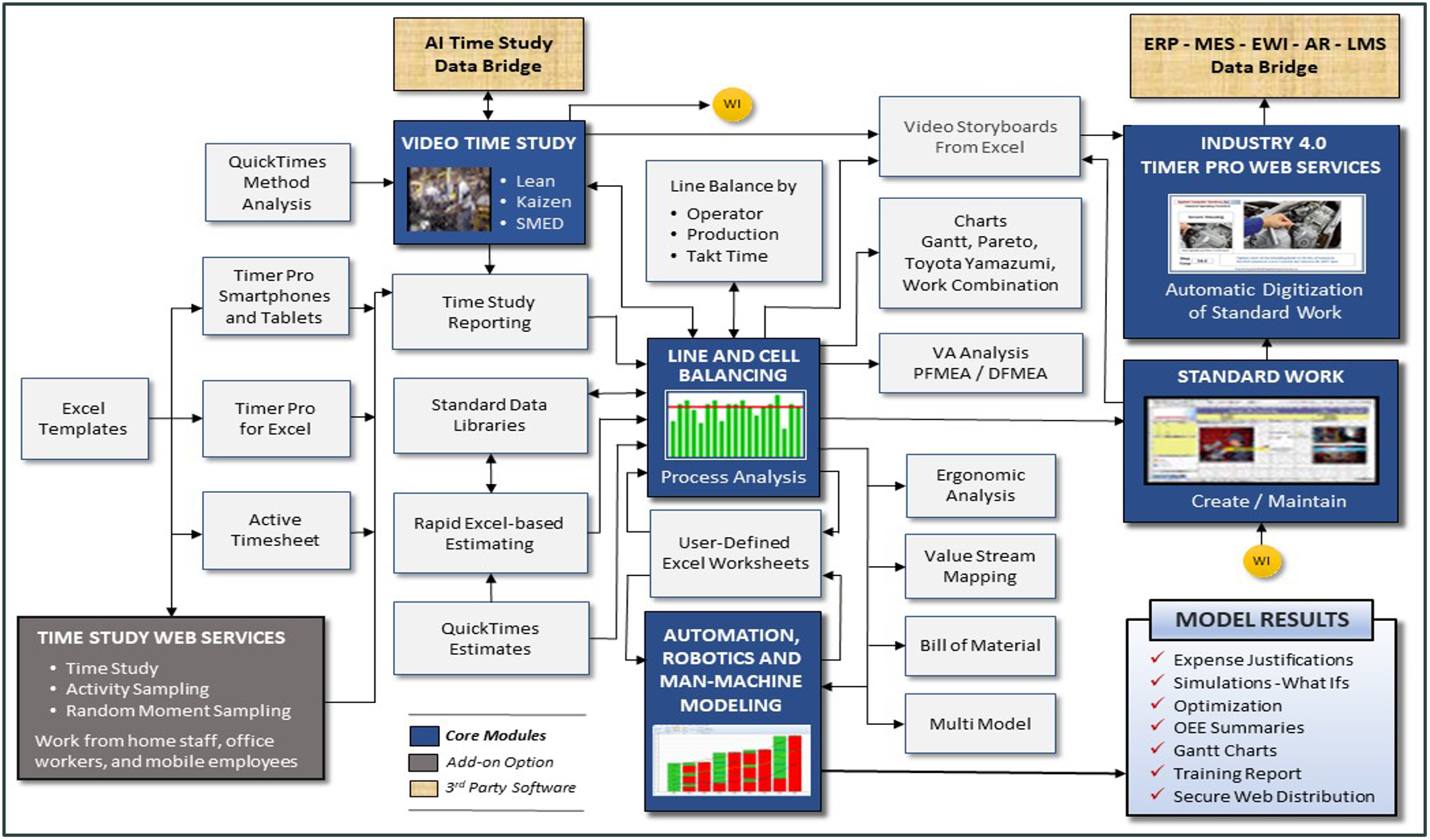

See All that Timer Pro Offers

The overview flowchart below presents Timer Pro’s features and structure. The menu options on the left allow you to explore more detail of specific capabilities that may be of interest. The Free Demo download on the right will let you experience the quality of Timer Pro first hand.

Click Image Below to Enlarge

Timer Pro Web Services

Timer Pro Web Services™ (TPWS) allows you to securely distribute your video work instructions, operator training and customer support video content to your internal and external end users.

In addition, TPWS supports secure distribution of your process models and results to your internal stakeholders or to potential clients if you are an automation, robotic manufacturer or integrator looking to differentiate yourself from your competition.

Google Unwanted Software Policy Compliance Statement

We hereby attest that the software application offered here is developed, owned and distributed by us for the purposes of process measurement to support your continuous improvement initiatives; will not affect the performance of your system hardware or change any system settings; is easily completely removable from your system; does not collect or transmit any private information in any form; is not bundled with any other software; is free of malware.