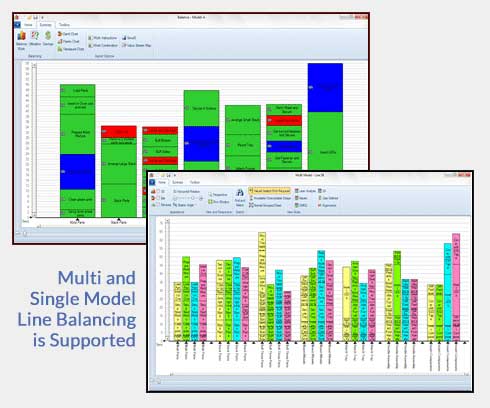

Line Balancing

Instantly Balance your Assembly Lines and Work Cells

Watch Videos: LINE BALANCING

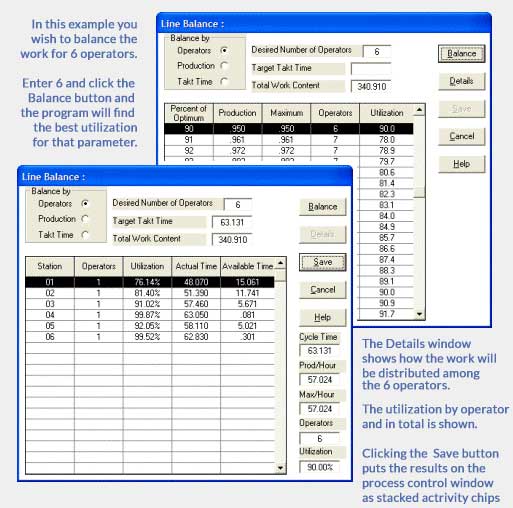

Timer Pro Professional’s Line Balancing module allows you to balance your work content by:

- Number of Operators

- Desired Production

- Takt Time

Drag and drop work content as required. It’s that simple. It’s that easy

Produce Toyota’s Yamazumi Charts, Gantt and Pareto Charts in Seconds

Line and work cell balancing is an effective tool to improve the throughput of assembly lines and work cells while reducing manpower requirements and costs.

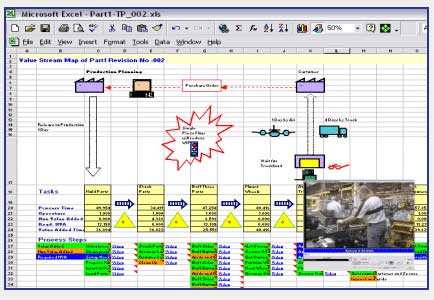

Value Stream Mapping

A single click will pass the current balance results into a Value Stream Map template. In this way you can easily map both current and future state conditions. The Value Stream Map is in Excel – no special software is required.

Google Unwanted Software Policy Compliance Statement

We hereby attest that the software application offered here is developed, owned and distributed by us for the purposes of process measurement to support your continuous improvement initiatives; will not affect the performance of your system hardware or change any system settings; is easily completely removable from your system; does not collect or transmit any private information in any form; is not bundled with any other software; is free of malware.